Conversion Related

This page will relate to information specific to fitting a VW Diesel Engine into a vanagon

Contents

Reference Material

- Here is my YouTube playlist of videos to this page. There's not as many videos as I initially thought. I think videos can move a bit quick and allow a miss of detail. That and uploading a large video over mifi is a challenge ;)

Part Reference

Part Vendors

Conversion Part Vendors

Service Manuals

- Bentley; ISBN 10: 0837603668

Social Media & Forums

Social Media

FaceBook has most of those groups

- Vanagon Owners Group - Overly moderated and free speech/thought is NOT encouraged.

Cooling System

Prerequisites

Coolant System - THIS allows the heart to beat and not overheat and die. It's ESSENTIAL to be in tip-top condition! Your diesel Vanagon's coolant system is HOW old? And you want to do WHAT type of conversion? Do this first if you haven't already!

Engine Mounts

Generally speaking, if you plan to have a larger turbo than a K03 or K03/04 hybrid such as a GT2052 or VNT20 turbo, you'll need to modify the driver side motor mount.

One can be custom made if fabrication skills exist. Or one can buy something already available and modify it to suit your needs. When I started my project, I didn't have fabrication skills as I later developed.

Driver Side Engine Mount Options

- EPYTEC 1z conversion mount - This is what I ended up with.

- Tony @ TSI Engineering - I would have went this route if I knew he made those along with the carrier bars!

Epytec

I ended up purchasing the Epytec motor mount which is stout and works out of the box for a K03 / VNT15 turbo.

However, it has it's flaws which are easily corrected if done right.

The two issues with this motor mount are

1.) They bent and shaped the mount properly, but failed to fill the bend/divets with weld filler to prevent crackts.

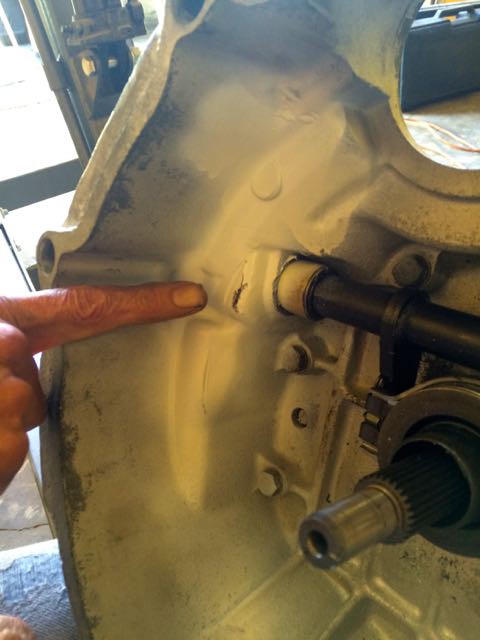

The photos below help show what I'm talking about.

2.) The bracket has a hump which is pointless that I see. It hits all the larger wastegate turbos. The area circled

Hack off the hump!

Now put something thick in it's place that's not as high up! This is raw to give an idea of what to do. After you weld something clean it up and repaint!

The change I did gave me a 0.25" of space between the wastegate and the mount. Perfect!

TDI LUK DMF (17-050) Clutch

This can be done on an AAZ or TDI (1Z, AHU, ALH) engines in a 50deg setup with a diesel vanagon bellhousing.

Get a modified TDI input shaft from Chris @ T3 Technique (ask him) or buy from Brickwerks here (input-shaft-t3-tdi) installed onto your transmission.

First cover the input shaft and Clutch Cross Shaft with masking tape. Then do a light spray of white spray paint inside the bell-housing. A very light spray. Then let that dry.

You'll at this point when the crank turns freely you'll want to mount up the DMF flywheel to the engine. Then mount up the tranny with the Bell Housing to the engine.

Once that's mated, try turning the crank. You "should" have interference. Go Clockwise till it stops then go CCW till it stops. Do this a few times.

Now remove your transmission & bell-housing.

You should see where the paint was rubbed indicating where to trim with a grinder to let the flywheel clear

Trim and remount and make sure it rotates cleanly.

Then remove the transmission and the DMF clutch/flywheel and put the DV flywheel/PP back on the engine.

Now mate up the transmission again so you have the BH mark for the Flywheel/PP. Turn the crank till you have TDC of the flywheel, then install your crank-lock tool from MetalNerd.

At this point TDC the IP and CamShaft as indicated above.

Once, everything is at TDC; crank, camshaft, and IP

You can now remove the DV flywheel/pressure plate

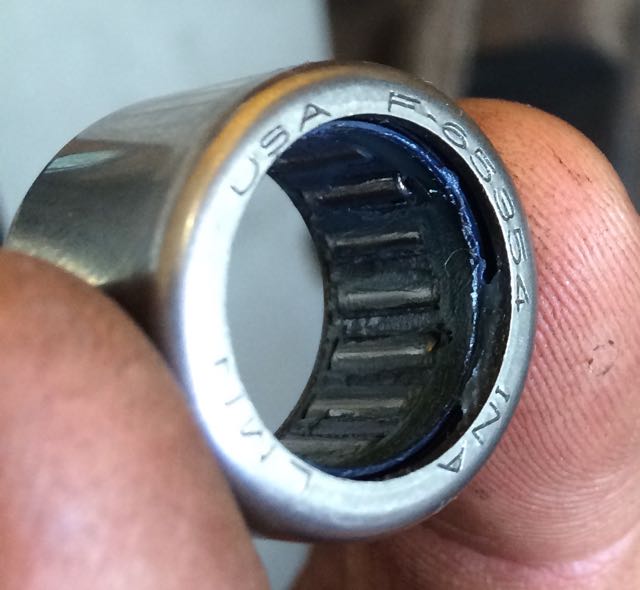

At this point you should install the pilot bearing lightly greased tapped into the spot on the engine

Install orientation

Installed

Install the TDI DMF Clutch/Flywheel.

Reinstall the transmission with the bell-housing.

Now, the BH will give a TDC mark of where the DV was that you now mark on your TDI DMF Flywheel/PP as indicated below;