Difference between revisions of "Betsy Bertha's m-TDI"

| Line 1,691: | Line 1,691: | ||

:* 1 x N01101011 - nut | :* 1 x N01101011 - nut | ||

| + | |||

| + | ===== Driver Side Bracket ===== | ||

| + | |||

| + | If you use a larger turbo you'll need to fabricate a bracket that'll fit it. | ||

===== Photos ===== | ===== Photos ===== | ||

Revision as of 03:55, 1 October 2016

IN PROGRESS! I will remove this notice warning when I complete my conversion and then add an 'updates' section,

Contents

- 1 About

- 2 Diesel Vanagon/T3/T25 Donor List

- 3 The Process

- 3.1 Preparation (clean up used AHU)

- 3.2 Long Block (BoraParts) build-up

- 3.2.1 Engine Cover Plate

- 3.2.2 Intake

- 3.2.3 Exhaust

- 3.2.4 Vacuum Pump

- 3.2.5 CrankCase Breather Valve Assembly

- 3.2.6 Oil Filter Flange

- 3.2.7 Oil Filter Union

- 3.2.8 Aux Oil Cooler

- 3.2.9 Oil Pan

- 3.2.10 Tooth Belt Guard Tensioner Roller

- 3.2.11 ABF Serpentine Setup

- 3.2.12 Intermediate Shaft Pulley

- 3.3 Coolant Pump

- 3.3.1 Reference

- 3.3.2 P/Ns

- 3.3.3 Tools

- 3.3.4 Installation Notes

- 3.3.5 Coolant Flanges

- 3.3.6 Diesel Injectors Install

- 3.3.7 Glow Plug Install

- 3.3.8 Coolant Pump to Block Coolant Flang Hose

- 3.3.9 Diesel Injection Pump Mounting

- 3.3.10 Diesel Injection Lines Install

- 3.3.11 Diesel Injection Pump Sprocket Install

- 3.3.12 Injection Pump Idler Pulley

- 3.3.13 Camshaft Sprocket

- 3.3.14 TDC Process

- 3.3.15 Clutch

- 3.3.16 Transmission

- 3.3.17 Turbo Oil Return Line to Block

- 3.3.18 Engine Carrier Bars & Brackets

- 4 The Details (my collected research before above work)

- 5 Part Purchase Notes

About

So, my mechanical experience is limited to working on an 1984 gas VW Rabbit when I was 16 in 1996. I bought that car for a $1! Too bad it was totaled by a mini-van running a red-light.

I'm an IT (UNIX/OpenSource) engineer by trade, but I have been working on my 1982 1.6na diesel Westy since 2012. So, I'm geeky, but new to being a mechanic to my van as much as I can.

It's all about self reliance!

Reference Material

- Here is my YouTube playlist of videos to this page

Part Reference

Part Vendors

Conversion Part Vendors

Service Manuals

- Bentley; ISBN 10: 0837603668

Forums & Social Media

Diesel Vanagon/T3/T25 Donor List

This is a list of items that you will need to source from an 82' or 83' USA diesel Vanagon or look over the pond at T3s

- Diesel Vanagon oil-pan

- Diesel Vanagon Transmission Bell Housing

- Diesel Vanagon Transmission Flywheel & Clutch (to later identify the TDI TDC mark)

- Diesel Vanagon engine mount brackets

- Diesel Vanagon engine carrier bars

The Process

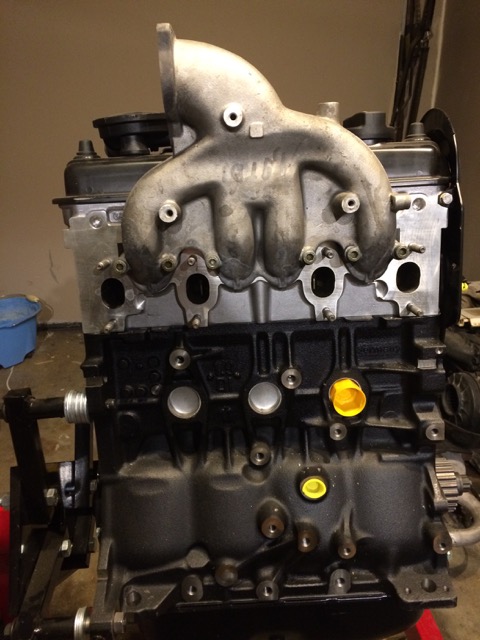

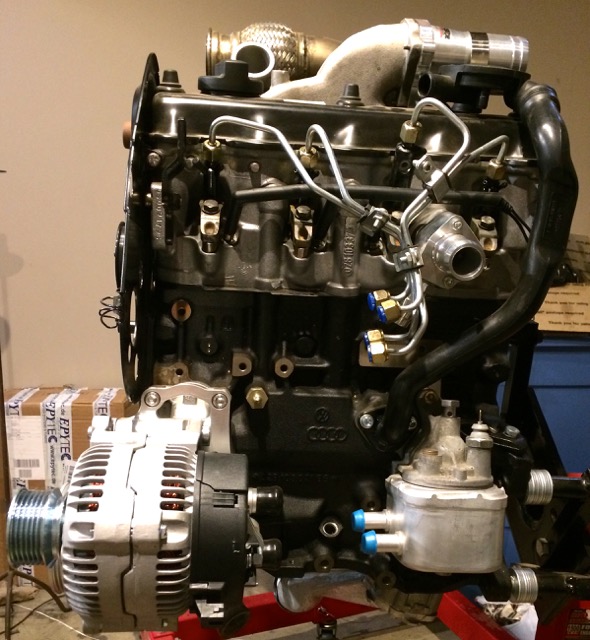

This is where I'm going to linking to my youtube videos regarding my steps of building up a new-long block AHU engine using a used complete engine from Quality German Auto in Ontario, CA as a reference. Then the used engine someday will be either a backup/spare or for another project.

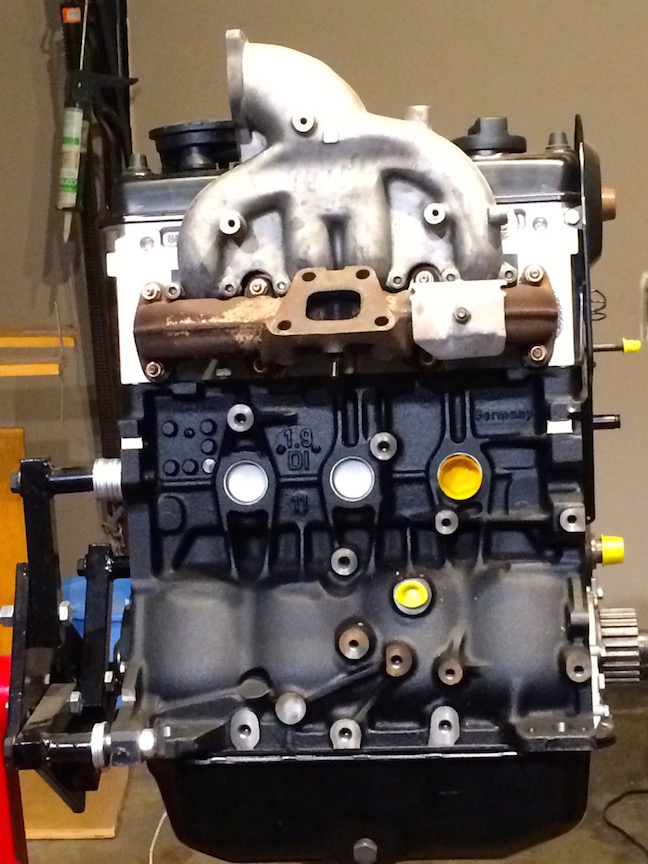

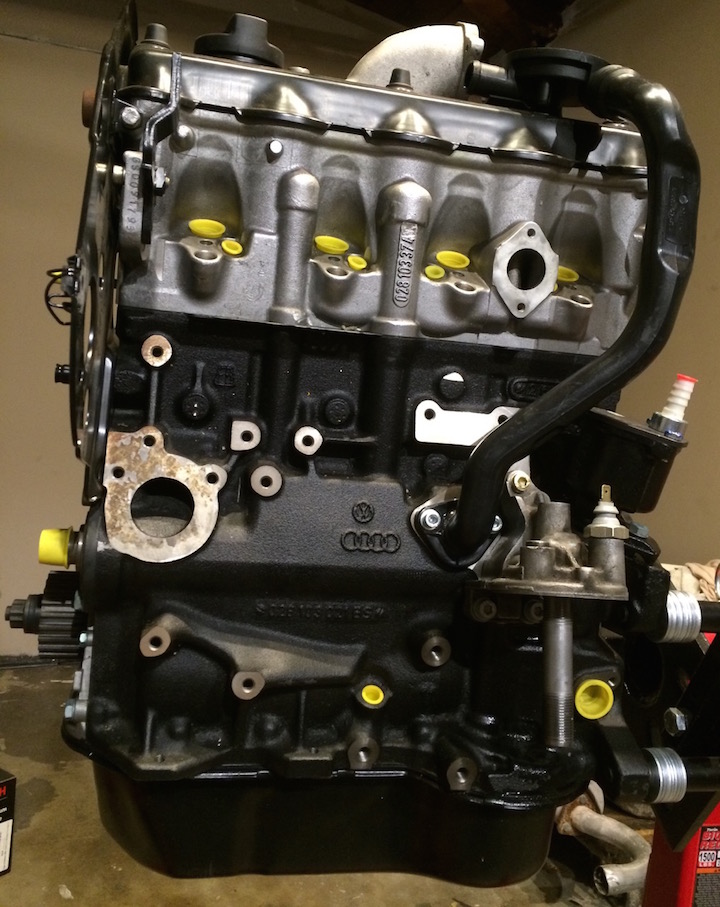

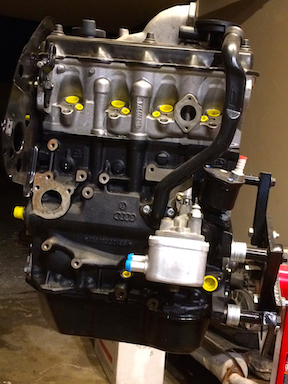

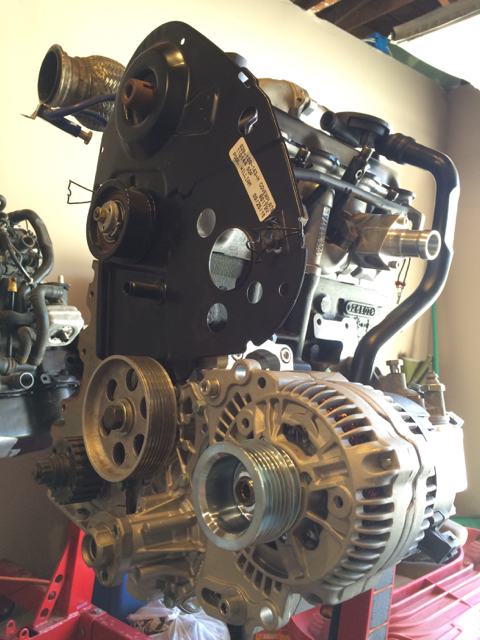

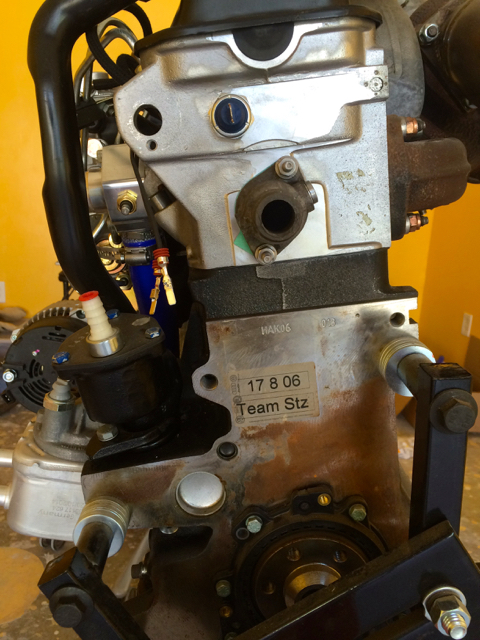

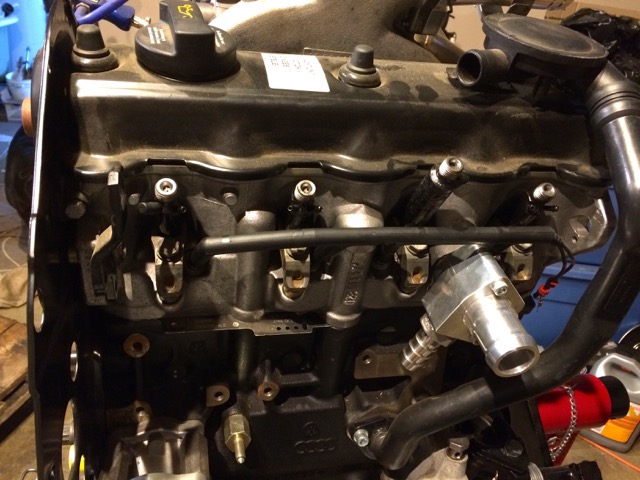

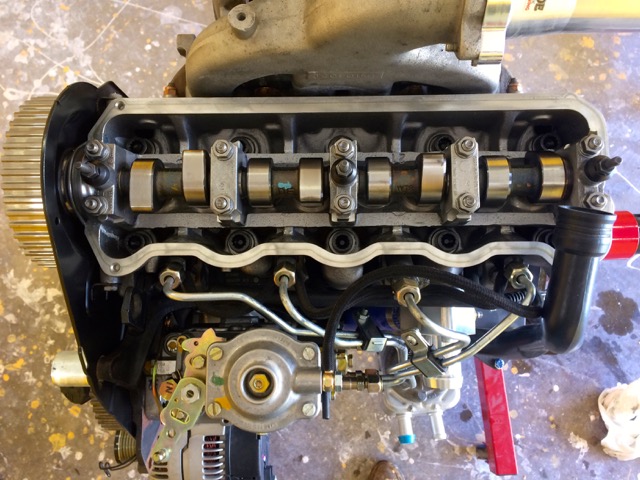

Here is the new long-block and used engine:

Preparation (clean up used AHU)

I bought two engine stands identical in the process of mounting the new long-block and the used engine onto for my work.

I first had to remove the clutch from the used engine to allow clearance with my mounting hardware to the stand.

Clutch Removal

Tools: 9mm 12-point socket & 17mm standard socket

Here is a photo of the 9mm removal

Heater Hoses & Engine Bracket Removal

The assembly is held together by some brackets and one nut head which can be seen below center photo between the two black hoses

Now remove this final hose

Now remove the other coolant hose

Video

Here is the video I made of the part I took off:

ECU / Wiring Harness

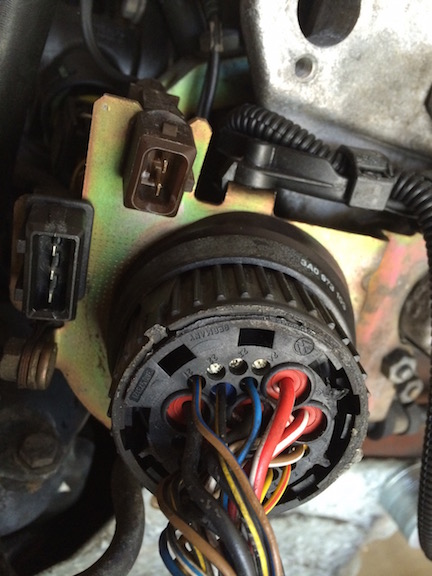

The side of the clutch top center there is a round cluster of wires and other plugs going into a central hub.

It looks like the below. I was able to disconnect everything but the glow-plug bar. I did the whole counter turn try and remove the plug, but no go. I just snipped the glow plug harness cable.

The rest I was able to unplug and the harness and all the wires came free:

What it looked like trying to get the two glow plug wires free

Videos

Video of what it looked like without the ECU wiring harness

ECU / Wiring harness removed - video

EGR Removal

You don't need the EGR! From what I have been told in the TDI Conversion list was the following from Karl M. @ link Westy Ventures: "In many early TDIs, EGR contributes a lot to the clogging of the intake manifold and ports. Many have deleted or blocked EGR on TDIs to avoid the buildup of nasty gooey carbon. There also is no easy way to control it on an mTDI."

Reference

- Bentley 26.1 - Exhaust System/Emission Controls

- Bentley 26-6 - EGR

- Bentley 26-8 - 1Z / AHU specific

- Bentley 26-9 - Fig 1

Videos

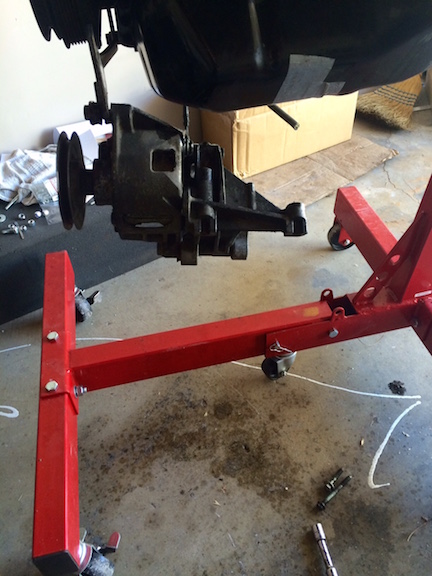

Power Steering Pump & Bracket Removal

The power steering isn't needed for the mTDI setup in my 82'. To get the used engine close to what I need to work with, I'm removing it.

That can be done via three bolts. Two at the bracket and one at the swivel.

Reference

- Bentley 48.15

Video

In the end after you remove the bracket bolts you'll just have the swivel bolt like below

Long Block (BoraParts) build-up

Engine Cover Plate

The new-long block didn't come with an engine cover-plate. This was purchased for the engine and the corresponding mounting hardware.

Reference

- Bentley 15a-11

Tools

Blue Thread Locker

Torque Wrench

10mm socket

P/Ns

- 1 x 028109143H - 1Z/AHU engine cover plate

- 2 x N01021226

- 2x N0122265

Install

I initially started with the 028109143H cover plate and the two bolts and washers that set it into place (N01021226 & N0122265)

These two 10mm bolts install at a torque pressure of 7ft/lb

Photos

Cover Plate

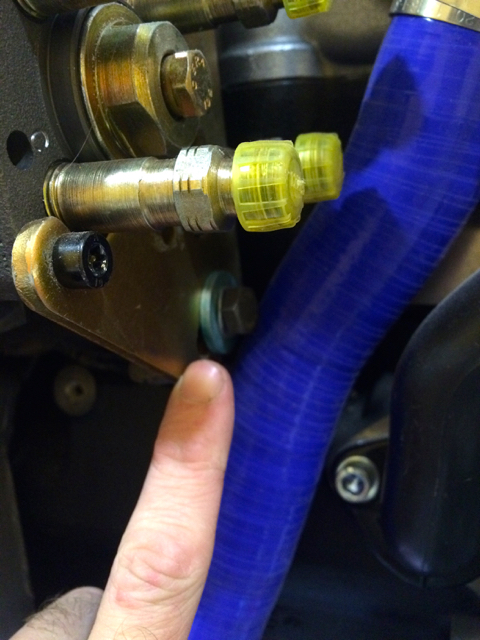

Where my thumb points is where the bolts go to mount the engine cover to the long-block

You see how it's mounted from the side:

Mounted from front

Intake

Reference

- VW; W42-011-294-103B 21-6

- Use high-temp (2000 F) anti-seize on bolts; blue

- Bolt hardware installed at 25Nm (18ft lb) or close to that with a torque wrench

Why PD130

The single large 3 bolt intake on the PD Intake Manifold that connect to your IC piping faces FRONT of the van typical on AHU install

These terms are used to describe the same thing

Driver side exit, right side , euro passat, longitudinal and is one of these part#

- 038129713AJ

- 038129713AG

The two above intakes would require an EGR delete down-pipe

However, if you have an intake with the p/n 028129713N which is from a Golf 1z setup would also work a-bit more restrictive with the air.

PD130 Install Notes

Intake PD130 038129713AJ

I wanted to replace the gasket and all mounting bolts

ID Parts Intake Manifold Cleaning Kit (AHU/1Z)

Which includes the parts laid out in:

ETKA 1997 Passat Diesel Intake Manifold

The kit itself includes what I need: gasket & mounting bolts

If obtaining a used intake (which is MOST likely the case there's various methods of cleaning it out.

In my case, I used multiple (two-three days twice a day)power-washings after they sat with oven-cleaner sprayed on their intake ports.

It should look like this before putting it on the long-block

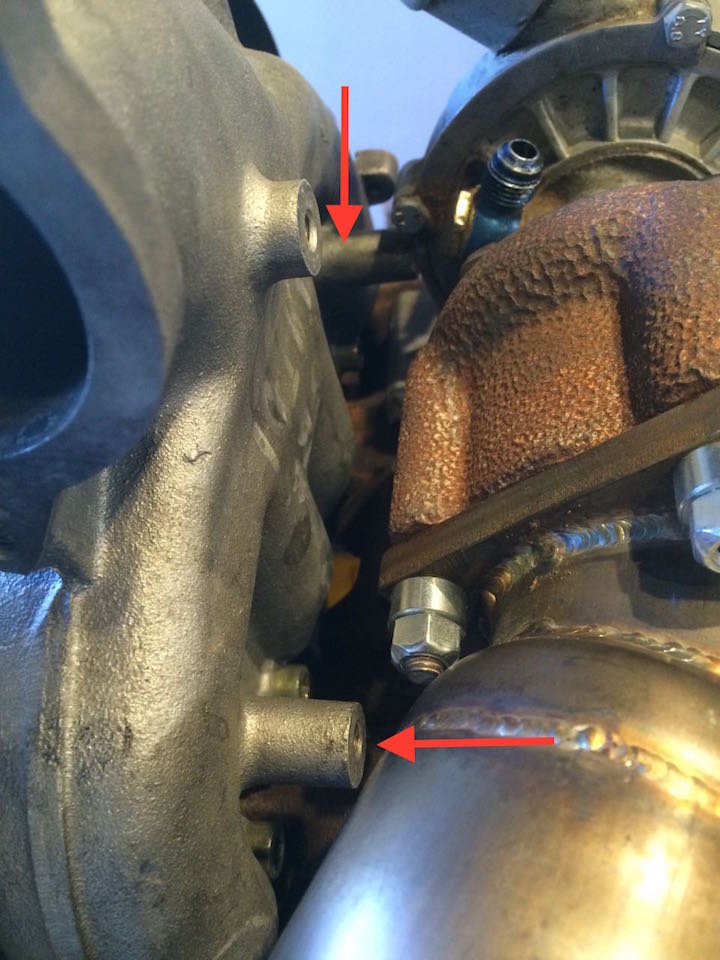

PD130 hack off bosses

The turbo isn't clearing the PD130 bosses and mating cleanly.

Here is a youtube and photo of what I'm talking about:

Arrows pointing where it is not clearing

Hack off the bosses!

Tools

- Torque Wrench

- H6

P/Ns

1 x 038129713AJ OR 038129713AG

Photos

Gasket Install

The raised side goes towards the intake manifold with the indented side going towards the head

Exhaust

NOTE: Before you start see the EGT Probe section below

I couldn't find the newer style as readily as the older style. I got a newer one for if I had to switch to it down the road.

Reference

- VW; W42-011-294-103B 21-2

- Use high-temp (2000 F) anti-seize on bolts to hold the copper exhaust nuts which are to be torqued @ 25nm (18ft lb)

NOTES

If using the AAZ exhaust manifold you position the turbo higher; thus, allowing to drain to the block instead of the oil pan.

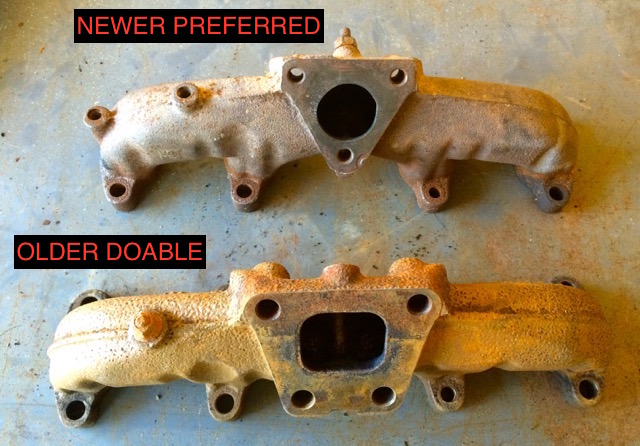

There are TWO types of AAZ exhaust manifolds that work for this.

The older trapezoid and the newer triangle, both will work

AAZ Exhaust Comparison

EGT Probe

P/Ns

- 1 x 068-129-591G - MK1 exhaust manifold trapezoid flange

- 8 x 116-217-119-54 - Copper plated exhaust manifold nut (8 per manifold) @ 25nm (18ft lb)

- 8 x N900-95-501 - Exhaust manifold OE washer

- 4 x 028-129-589B Exhaust Manifold Gasket.

Tools

- 12mm socket

- Torque wrench

- Permatex Ultra Copper

- Blue LocTite

Gasket Install

Per Libby: "The metal ring on the exhaust manifold gaskets can face either the head or the manifold and in fact, two *should* face the head and two should face the manifold. There is a horizontal line of symmetry through the exhaust manifold, but if you place a vertical line through the fastener holes, the ports are offset 4-5mm toward the center of the engine. In other words, the two ports on the pulley end of the head are offset toward the flywheel and the two at the flywheel end of the head are offset toward the pulleys. The exhaust gaskets need to be oriented so that the offset is the correct direction. Furthermore, if you look where the gasket surrounds the stud, there is a skinny side and there is a side that has more material. The skinny side should be oriented closer to the intake manifold."

Then a light smear of permatex copper on both sides of the exhaust manifold gaskets

Here is how the gaskets should look orientated before the permatex sealer

Video

Photo

EGT Probe

Reference

Photos

Vacuum Pump

I had made a video, but I lost it. This is a very simple process, so I will just explain it here.

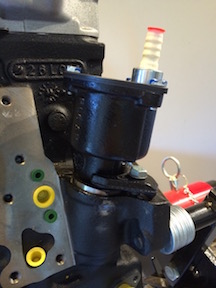

If you look at the end of the vacuum pump you'll see it has a slot. Then when you look into the engine hole a receiver for that slot. The goal is to lube it up a little with diesel oil so it's not totally dry. Then go in the angle of the slot. I usually turn clock-wise till it falls seated. One way of knowing if it's seated or not is you won't be able to see the greenish/gray O-ring as shown in the photos below. Then just tighten up the bolt and bracket. In order to get the bolt to even up enough to screw into the hole for the bracket, you may have to wiggle the bracket a little.

Reference

VW Repair: W42-011-294-103B p13-10

Tools

- 13mm open-wrench

P/Ns

- 1x 028145101A - AHU vacuum pump

- 1x N0102336 - hexagon bolt; M8X28 (13mm @ 20nm)

- 1x N01224110 - spring washer; B8X15

- 1x 028905256 - bracket

- 1x 068145117B - Vacuum Pump Bottom Sealing Washer

Photos

Final photos of installation

CrankCase Breather Valve Assembly

Reference

ETKA - Ventilation for Cylinder Head Cover Diagram

P/Ns

- 1 x 028129101D - PCV/CCV Valve (A3) (B4)

- 1 x 028103491J - CCV Breather Tube (A3 B4 AHU 1Z)

- 1 x N 90466301 - o ring for breather tube

- 1 x 028103500 - CCV Valve Rubber Boot

Tools

- Blue coded thread-locker was used on tube mount bolts.

- H6 @ 7ft lbs

Photo

The red oval is the only bolts you have to tighten and the puck at the top goes into the breather hole

Oil Filter Flange

NOTES

- 053115417A - Oil filter flange; This flange has been used for all the 1.8-1.9 gas and diesel engines (AAZ, 1Z and early AHU). The difference being the later AHU adaption have two 10mm ports and one 12mm port (for the Banjo Bolt N0210717) instead of the three 10mm ports that the gas/ABA engines use. There's no 'real' way to know which you get by searching for the P/N. Your best luck appears to be searching for a "MK3 TDI oil filter flange" or maybe "AHU" also in the search string.

There's also two other indicators of the proper one you received.

First the third port is larger than the first two. (photo coming soon of comparison)

The second visual indicator is a bit more positive you got the right one from what I have read on the forums and Parts Base.

Within the below photo in the red circle is 028115436 - choke; M12X1,5; AAZ,,AHU,1Z which is what you want for the diesel engines. From my research, and what I received the first time, gasser engines do not contain this.

Reference

VW Repair: W42-011-294-103B p13-10

Tools

- Blue Thread Locker

- H6

P/Ns

- 1x 028115436 - choke; M12X1,5; AAZ,,AHU,1Z

- 1x N0160243 or N0160241 - sealing plug; M10X1; ADD,AHU,1Z

- 1x N0138115 - o-ring; 10X13,5; ADD,AHU,1Z

- 2x N0903151 - socket head bolt with hexagon; socket head (combination); M8X25

- 1x N90425401 - socket head bolt with hexagon; socket head (combination); M8X40; ADC,ADD,ACC,; AHU,1Z @ 25Nm

- 1x 028115441C - oil filter seal

- 1x 068919081A - Oil Pressure Switch [OEM] (A3)(B4)

- 1x N0210717 - Oil Filter Oil Feed Line Banjo Bolt

Photos

Here is the oil filter Flange installed:

Video

Oil Filter Union

This is maybe the easiest part to install. You just screw it in. I put some blue thread locker on it. It doesn't matter which end screws into the oil-filter.

P/Ns

1x 028115721B - union tube

Photo

End result:

Aux Oil Cooler

Reference

P/Ns

- 1x 028117021E - oil cooler

- 1x 028115721B - union tube

- 1x 068115723 - hexagon nut; ADC,AAZ,ABA,; AHU,1Z

Installation

This is pretty simple just slide it over the (028115721B - union tube) into the oil-filter assembly. The ports will face left of the engine indicated in the photo below. If you look at the top of the cooler and inside the flange you'll see the 'oil' feed line hole. Those basically need to match up.

Then place the oil-cooler over it and attach with the (068115723 - hexagon nut)

Photo

End result:

Oil Pan

This section will include details on swapping the 1.6na DV oil-pan for a 50 degree install, as also the 4cyl windage tray for it. At the same time we'll be swapping in an 82' diesel oil-pump to get the desired plunge shaft length.

NOTE: You must leave the oil-pan loose and mate to the transmission first THEN once the transmission is mounted tighten up the oil-pan along the edge level to the block.

Reference

- VW; W42-011-294-103B 13-12

Tools

- 13mm socket 6point

DV Pan swap to AHU

Its as recommended to get longer oil-pan screws for the windage tray, but the stock 1.6na CS engine DV pan comes with the following 20 bolt sizes:

- M6X16

- M6X22

- M6X25

So, you could get lucky with two of the three possibliities, but you may want to measure the oil-pan bolt first.

However, the AAZ which does come with the windage tray comes with:

- M6X17

Since the above bolt size was supposedly used with the 1Z and AHU still,

These should be tightened to 20Nm

Now for the actual windage tray itself. It was included with the AAZ and sometimes with the 1Z and AHU engines, but was more common in the gasser inline 4's. It was NOT part of the 1.6na engine.

That said, my 1Z came with a windage tray, but sometimes the sealant is so bad it fucks the seal up and you'll need to get a new one.

The Windage Tray P/N is: 028-103-609A

DV Oil Pump Swap

You need to use the DV oil-pump NOT the AHU oil-pump; unless you modify it.

Reference

- Bentley 17-1 - 1Z / AHU specific

- VW W42-011-294-103B p17-6

Once you have the oil-pan off the AHU you'll see the oil-pump. However, if you're long-block is like mine it may have a windage tray installed.

P/Ns

- 068-115-105BP

Photos

AHU Windage Tray Installed

Now you'll see the oil-pump as the silver device with the black tray delay off to the left. This is the oil pump you need to swap.

Here is the AHU (black part on it) oil-pump vs a new DV oil-pump

You'll see two bolts (black heads for me) where my fingers point. These will remove the oil-pump (13mm)

When installing the DV oil-pump the two pump bolts get torqued at 20Nm

NOTE: The AHU oil-pump bolts are LONGER than the DV oil-pump bolts. If you do not have the original DV Oil Pump bolts you need to get two of either of the following P/Ns: N01037510 or N0103753 with the spring-washers N0122265

Installing Oil Pump & Windage Tray

See the note above about final tightening that happens AFTER the transmission has been mated to the engine! When ready to tighten, use blue thread locker for the bolts. It helps keep everything snug.

I've seen two types of AHU windage trays. OEM and from Victor Reinz. The VR ones are slightly larger where they can with caution and care fit over the DV oil-pump. The OE ones do not.

I just suggest installing the pump first (the bolts will be 13mm tigten to 20Nm) and with blue thread tocker. At that point you can let the windage tray hold on the pump like this

Then put on the oil-pan with the bolts hand-tighten / semi loose, as to protect the pump. You should have something like this

Tooth Belt Guard Tensioner Roller

Reference

P/N

- 1 x 028109243F

Tools

- 13mm socket @ 25Nm

Installation

Very simple just slide it over, lock the latch into the engine cover plate. Then tighten the nut @ 25Nm

Video

Photo

This is a photo of where the locking slot of the tensioner goes

ABF Serpentine Setup

Since I don't have power-steering nor do I have air-conditioning, I can simplify my setup and make it more reliable with a serpentine setup rather than a v-belt system.

This can be accomplished via various methods as mentioned below. I went the ABF way

Reference

I ended up using a system from iABED Industries found on the VWVortex

He makes a custom bracket, that's really beautiful, but if you want to source / find your own VW specific parts read these threads:

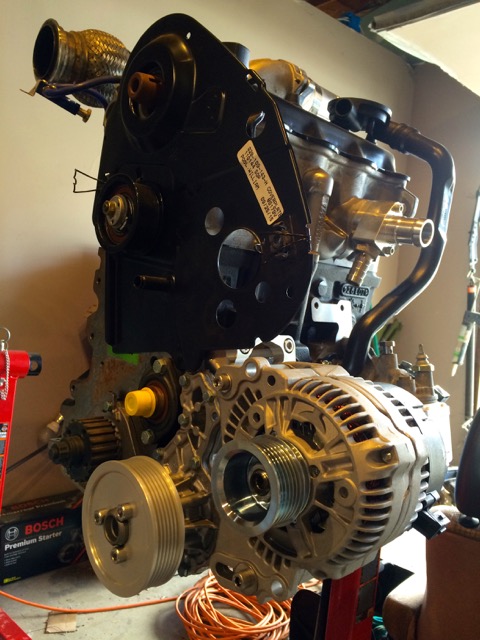

The Alternator I ended up using was an ABF Bosch reman 90a - AL0187X (VW # 028 903 025 P)

Photos

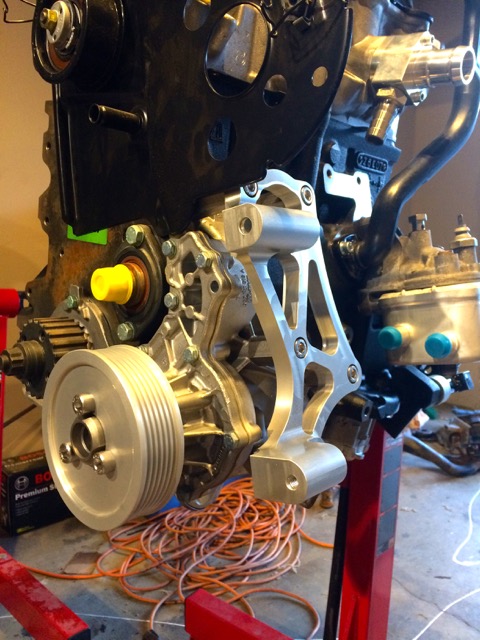

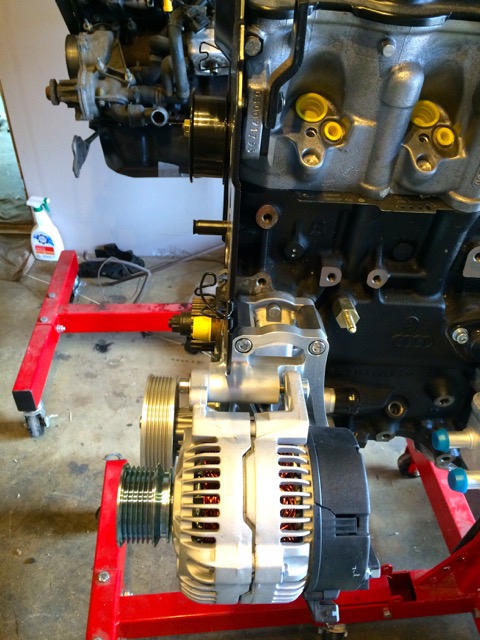

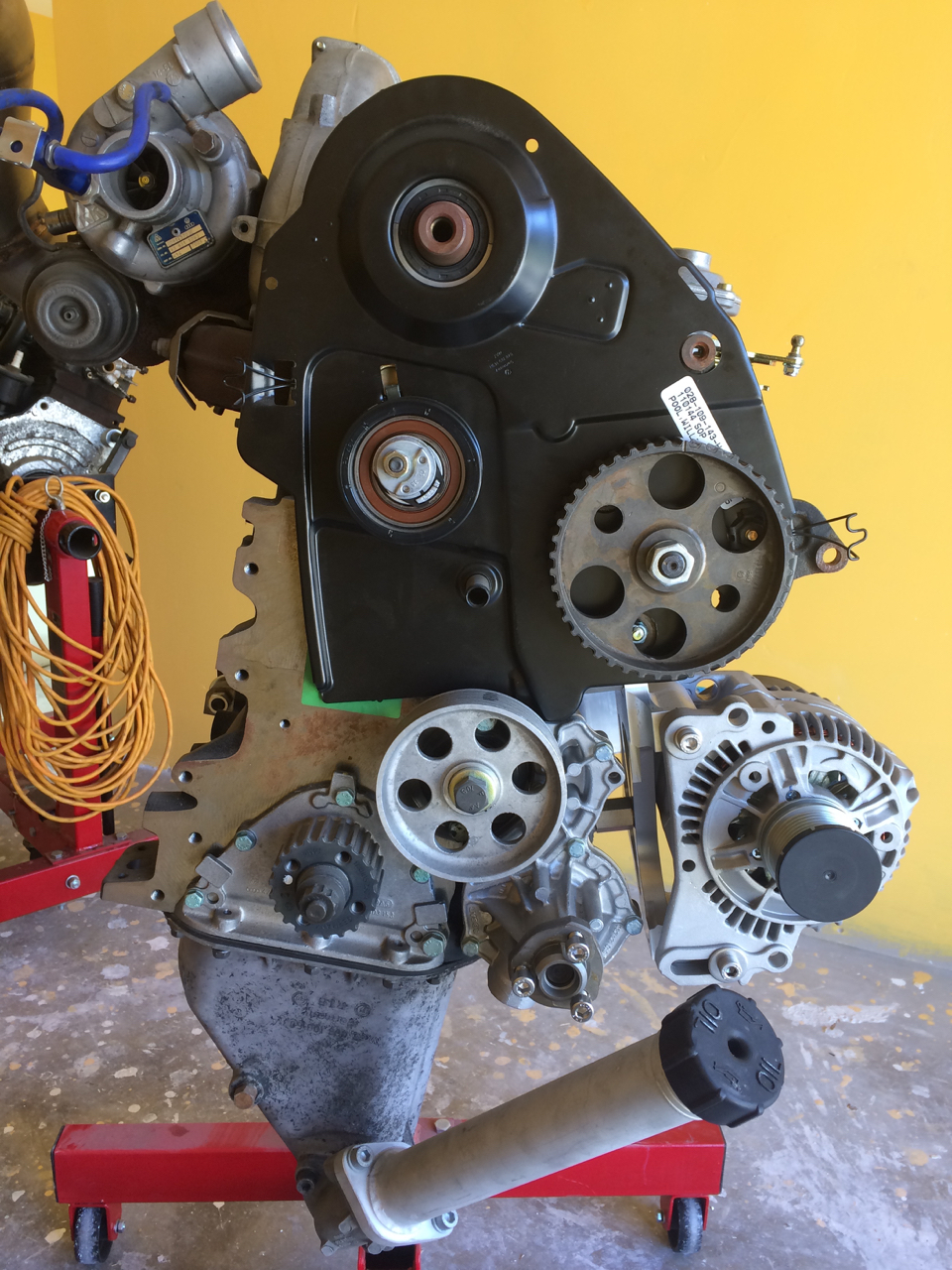

iABED Industries ABF Bracket

Alternator installed with the bracket and pulley's installed.

Intermediate Shaft Pulley

Reference

- MyTurboDiesel - Intermediate Shaft Seal Replacement Guide - If you want to replace yours. Mine on the long-block looked new.

VW; W42-011-294-103B 13-4

Tools

- Blue Thread Locker

- 22mm socket

- Sprocket Countersink Tool

P/Ns

- 1 x VW# N012708 - 2sprocket woodruff key

- 1 x VW# 028-115-017E - intermediate shaft (in case yours is broken, don't have one off a used engine, etc.) The part numbers / VW logos go towards the engine (i.e. where you can't see them)

- 1 x VW# N0101371 - Hexagon Bolt M12X1,50X35 @ 45 Nm / 33 ftlb

- 1 x VW# 027109143 - washer

- 1 x intermediate shaft /camshaft seal (47x32x10mm) "026 103 085 d" or "068 103 085 e"

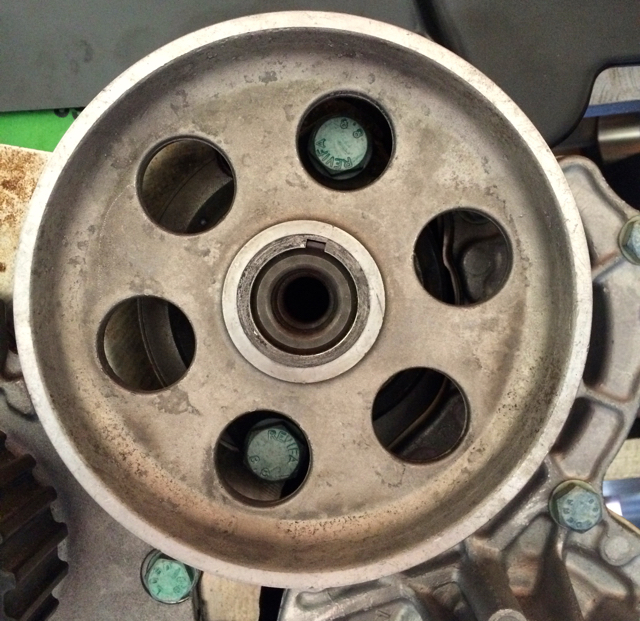

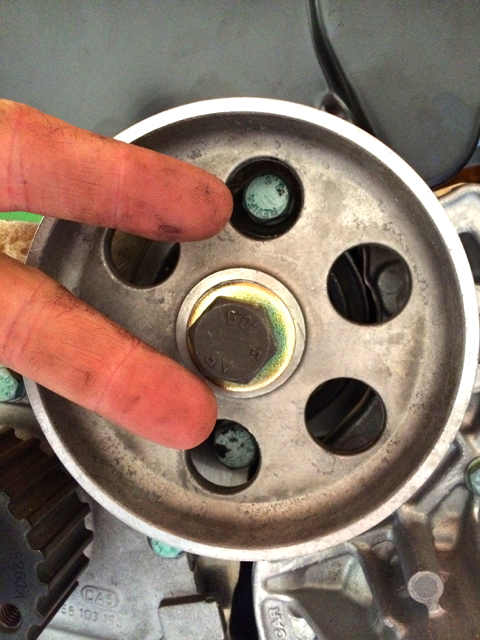

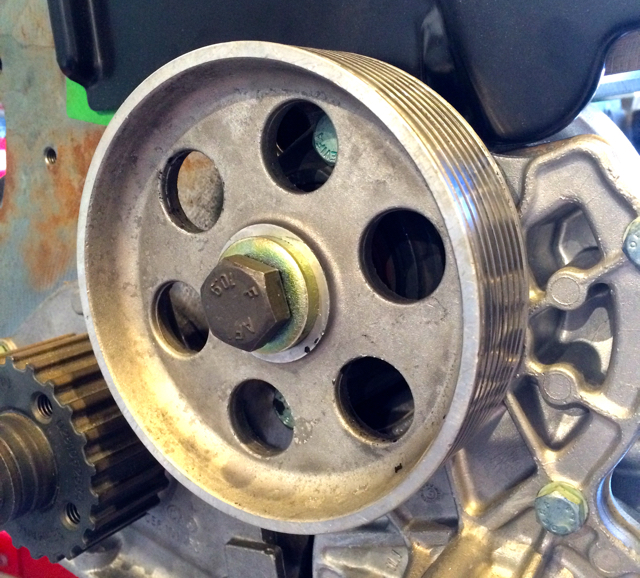

Photos

Sprocket Tool

This is the tool / setup you want to remove/install. This was on my used engine, but same applies for this build-up.

Intermediate Shaft Parts

You should have these parts

Intermediate Shaft Woodruff Key Install

Position it like this:

Then set it into the groove like this:

Intermediate Shaft Mounted

It should slide on like so:

Sprocket Countersink Tool Mount Points

Place the sprocket tool at these locations when you tighten the center bolt

Intermediate Shaft Pulley Installed

It should look like this when done

Coolant Pump

Reference

- VW; W42-011-294-103B 19-6

Serpentine or non

http://www.thesamba.com/vw/forum/viewtopic.php?p=7673431#7673431

If you don't have A/C or PS, you can use the VR6 water pump pulley (028-121-031-E) and use the serp belt to run the Alt and water pump.

Decided to get a serpentine setup done via INA Engineering:

http://forums.vwvortex.com/showthread.php?3871186

http://forums.vwvortex.com/showthread.php?3379568-ABF-alternator-bracket-Part-number

http://forums.vwvortex.com/showthread.php?3335420

P/Ns

- 1 x 037-121-013A - Coolant Pump Assembly

- 1 x 056-121-121B - Alloy thermostat housing

- 1 x 4256.87D50 - 87 degrees thermostat

- 1 x 038-121-119B - o-ring

- 2 x N902-809-04 @ 10Nm

- 1 x 037121121A - Pipe Union

- 1 x 1H0121687A - o-ring; 28,5X3,8

- 1 x 038-121-119B - o-ring; 50X4

- 1 x 028-260-821 - stud with shoulder

- 2 x 028-260-821A - stud with shoulder

- 1 x 028-260-821D - hexagon bolt; M8X34

- 1 x 028-260-821C - stud with shoulder; M8X17X24

- 2 x N 902-80-904 - hexagon head bolt (combi); M6X22

- 3 x N903-08-607 - socket head bolt with; inner multipoint head; M8X14

- 1 x 056-121-121B - this is NOT the normal AHU thermostat housing flange. Instead it's the one used for the 1.6na engine. However, it is a metal alloy and more durable than the newer plastic ones. It also has the proper hose fitting for the vanagon diesel hoses.

- 6PK1045 Serpentine Belt; Alternator

- 028-121-031-E - VR6 Water Pump Pulley P/N if you use this setup over the serpentine setup

Tools

- Blue thread Locker on bolts

- 19mm wrench

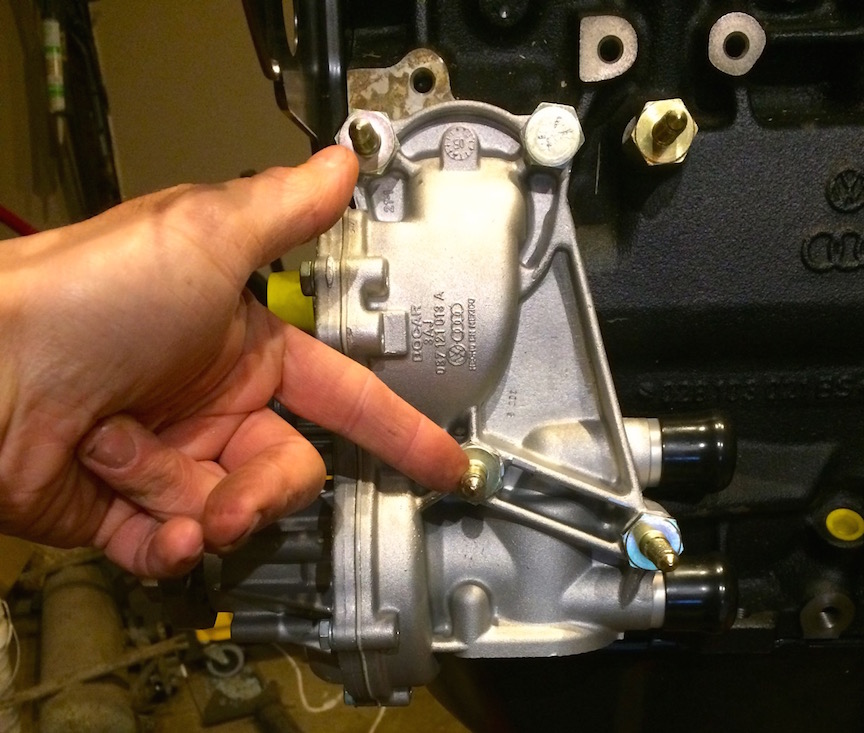

Installation Notes

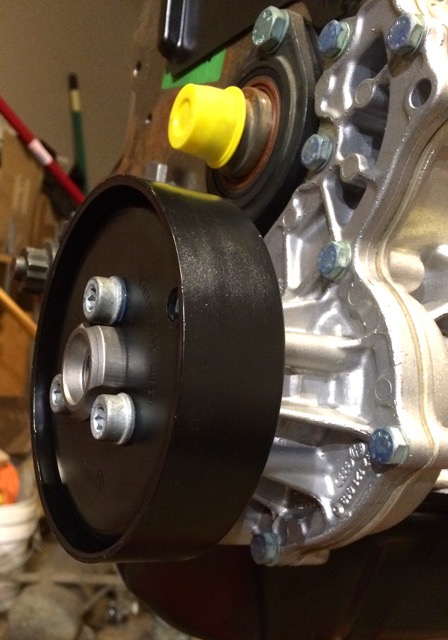

NOTE: don't put the pulley on till you are ready to put the lower belt cover on. Otherwise you'll ust be taking it off again down the road; learn from me!

Make sure your coolant pump came or you purchased the o-rint that goes between it and the long-block.

There are three shoulder bolts that look the same;

- 1 x 028-260-821

- 2 x 028-260-821A

The one my thumb is pointing to is 028-260-821 which is shorter than the two 028-260-821A that my index finger points to

The other two which are not clear in the reference points go as the following:

- 1 x 028-260-821D - hexagon bolt; M8X34 - This is the first one to the right of 028-260-821.

- 1 x 028-260-821C - stud with shoulder; M8X17X24 - this is to the right of 028-260-821D

Water Pump Pulley - OLD Non Serp Setup

This is what I intended to use, but later changed to something else. A simpler ABF serpentine setup which I'll reference when I start that.

- Tighten bolts to 25Nm

Tools

- Torque Wrench

- H6

- Screw Driver

Installation Notes

There's a round hole on the pulley that you can put a screw driver into to lock it so it doesn't turn while you tighten the bolts.

Proper Tool Warning!!! I found out after doing this from a peer-reviewer the tool you want is the water pump pulley tool. You can find it under one of these reference P/Ns:

- 96280, SCH96280, UN1203280

In the photo below you can see it going right from the top bolt.

Also, note the deeper part of the pulley goes towards the engine or the VW P/N faces away from the engine.

Thermostat & Housting

Reference

- VW; W42-011-294-103B 19-9

Tools

- 10mm socket

- Blue thread Locker on bolts

Installation Notes:

When screwing the housing to the water-pump, it may not look like it will seat in; however, the more you tighten the bolts the more it will slide up with the O-ring.

P/Ns

- 1 x 4256.87D50 - 87 degrees thermostat

- 1 x 038-121-119B - o-ring

- 2 x N902-809-04 @ 10Nm

Photos

The thermostat housing used from a 1.6na engine. It's an alloy one:

This is how the mounting orientation should go against the coolant pump

How it all looks installed

Coolant Flanges

References:

- ETKA - 1982 Vanagon, coolant hoses and pipes DIESEL:CS - This helps show where on the CS it's flange would go

- ETKA - 1997 Passat cooler for coolant reservoir flange - This helps show where on the AHU it's flange would go

- Samba - AAZ Coolant Sensor

Block to Pump Flange

I thought long and hard how to approach the mTDI coolant flange dilemma.

There's a few various options to accomplish this:

- Use the 1.6na aluminum flange p/n 068-121-133M with an adaptor plate to position the adaptor similar to the AHU orientation. The photos I saw of this looked like it'd cause a possible other leak, looked hooky, and just bad in my eye.

- Use the later AAZ sensor p/n 357-919-501

green ring) on the plastic AHU flange p/n 028-121-132A This solution is bad for two reasons to me. First it's plastic and in my mind more prone to cracks. Second now you've mix-matched the sensors on the engine.

- Custom baby!

In the end I felt a custom solution was the cleanest and best solution. For the following reasons:

1.) The material will last the lifetime of the van similar to how the 1.6na flange would; however, using the 1.6na flange you have to modify the hose route which isn't too clean to me; more parts. Or you would have to create a modification plate which in the photos I saw looked kinda hooky more possible leaks.

2.) I could have went with the normal flange itself and blocked the over-flow barb (which over time may need replacement) and used a later AAZ temp sensor (for coolant temp & glow plug), but then you have a mix-match set of sensors on the van. This would make over-all support a bit more "specialized". The custom flange mimics the diesel setup to the T.

I already have a sensor at the front of the engine block for the glow-plug, so that'd just be 'blocked up' using an AHU flange which is dumb. The engineer in me says mixing sensors makes supporting more a chore.

Custom mTDI AHU diesel vanagon coolant flange from Legacy Mold & Tool talk to Charlie! (502) 348-8151

NOTE: The correct hose barb I have installed is a 3/4" NPT to 1" ID (the one pictured be low is a 3/4" ID which I found out was wrong)

NOTE: The bolts on the flange are M6x55 and torque at 7nM, just use blue threadlocker and tighten snug by hand

Photos

Comparison to the CS one (068-121-133M):

End of Head Flange

Also, I am trying to swap the AHU flange 028121145 (Flange With Glow Plug Mounting) with a 1.6na 068121145K one.

There are two 1.6na flanges one with two sensor ports another with one. If you get the two version and want the plug a hole get the following o-ring and plug:

Tools

- Blue thread locker

- 14mm wrench

- 10mm wrench

- H5

Mounting Bits

- 1 x Plug: N0160243 or N0160241

- 1 x O-ring: N 0138115

- 1 x Flange Gasket 056-121-149-A

- 2 x N122265 washer

- 2 x N01021710 bolt

Photos

Using the 1.6na cylinder head coolant flange

Diesel Injectors Install

Bozzio Sprint 520's. They are supposed to be equivalent to the nozzles that came in the european delivered TDI's.

http://forums.tdiclub.com/showthread.php?t=276798&page=4

I ended up going with BOSIO DLC764s

Reference

P/Ns

Injectors

- Injector #1 #2 #4 - 028130202P

- Injector #3 - 028130202Q

Injector Holders

- 4 x VW p/n 028-130-206

- 4 x VW p/n 028-103-316A (the metal spacer)

Injector Nozzels

NOTE: What type of nozzles to use are more a personal preference of what you're give/take on the engine's performance you want to have.

Okay, it's likely you'll end up with a pair of used injectors, and you'll want to get them tested and put some new nozzles on them.

Very few place allow installation of customer supplied nozzles, so you usually buy the nozzles at the same place you do the calibration/mounting etc. I used KermaTDI

I went with Bosio DLC 764's for my nozzles.

Tools

- 17mm wrench

- 15mm wrench

- 13mm socket

- 10mm socket

- Ratchet and various extensions Torque wrench

Installing Injectors

You may or may not have the banjo bolt for injector #3 the parts for that are:

- 046130121A - banjo fitting

- 028130315 - banjo bolt

- N0138042 - O-ring

This part is assuming you have either cleaned/calibrated the used injectors you're using as install any new nozzles. If in doubt give KermaTDI a ring!

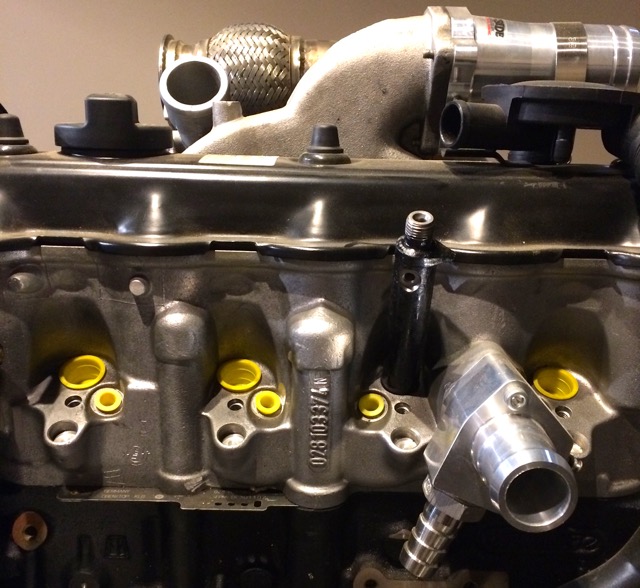

Four injectors with DLC764 nozzels from KermaTDI

Next I usually install the #3 injector first. This will be the only one with a screw hole on the side. It should fall into place, makes ure not to scratch the nozzle!

All four injectors installed

Once the injectors are in it's time to install the spacer & holder.

First the spacer goes in like this. You can see the bevel should face up as the way I am holding it

Here's the holder bolt, it goes in like this orientation. The curved part of the washer faces down

Here's the holder installed with the injectors

At this point you can install the banjo, banjo bolt, and banjo washer/oring for injector #3. The washer/o-ring goes towards the injector hence, in the orientation I have it held, it'd fall off the bolt.

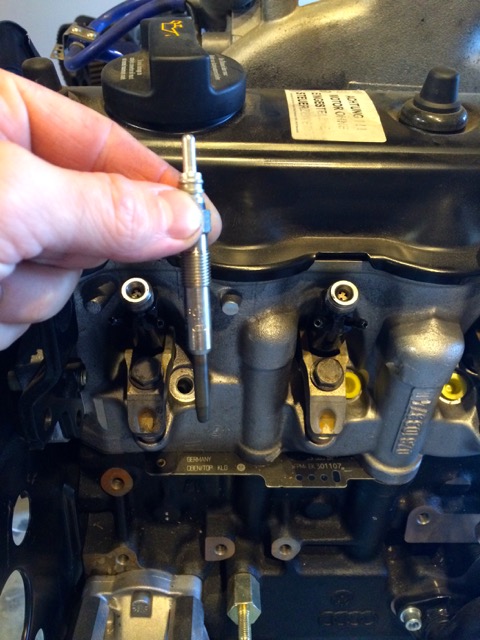

Now that the injectors are in, it's the best time to install the glow plugs

Once, the glow-plugs are in, install the injector lines and tighten snug with a 17mm

Glow Plug Install

Reference

Tools

- 10mm deep socket

P/Ns

- 028971766 - VW Early TDI 2 Wire Glow Plug Harness (’96-01)

- 0250202022 - VW 1Z AHU ALH TDI Bosch OEM Glow Plug Set ('96-03)

Photos

Harness with new glow-plugs

Orientation the glow-plug goes into the block

Glow Plug Assembly installed (wire goes towards the clutch)

Coolant Pump to Block Coolant Flang Hose

It may seem like an odd place to put this, but it's wise to install this hose first before putting on the IP. The IP will be a blocker to a point.

Hose # 3237850012

With my custom coolant flange, I needed to trim about 3/4" an inch off to have it fit, but in the end it'll look like this.

Diesel Injection Pump Mounting

References

P/Ns

- 3 x N10226004

- 3 x N01224110

- 2 x N0111849 @ 25Nm

- 1 x 068130173B - arm

- 1 x 068130174 - arm

- 1 x N90477301

- 1 x N01033512 @ 25Nm

- 1 x N0110212

- 1 x 068130199

- 1 x 068130197 @ 25Nm

Tools

- Blue Thread Locker

- H6

- 10mm wrench

- 22mm socket

- Universal Sprocket Buster Counterhold Tool

Photos

Main bracket mounted to the block with the three bolts

Set the IP into it, you'll see the front holes line up with the two holes.

Once per the video for the IP arm installation to the engine is complete you need to install the rear bolts from ETKA #13,14,16,17,5

This photo shows where they install:

The bolt should be setup like this:

And go in the back like this:

Now the plug-nut which is this:

Now install with the orientation shown here @ 25Nm

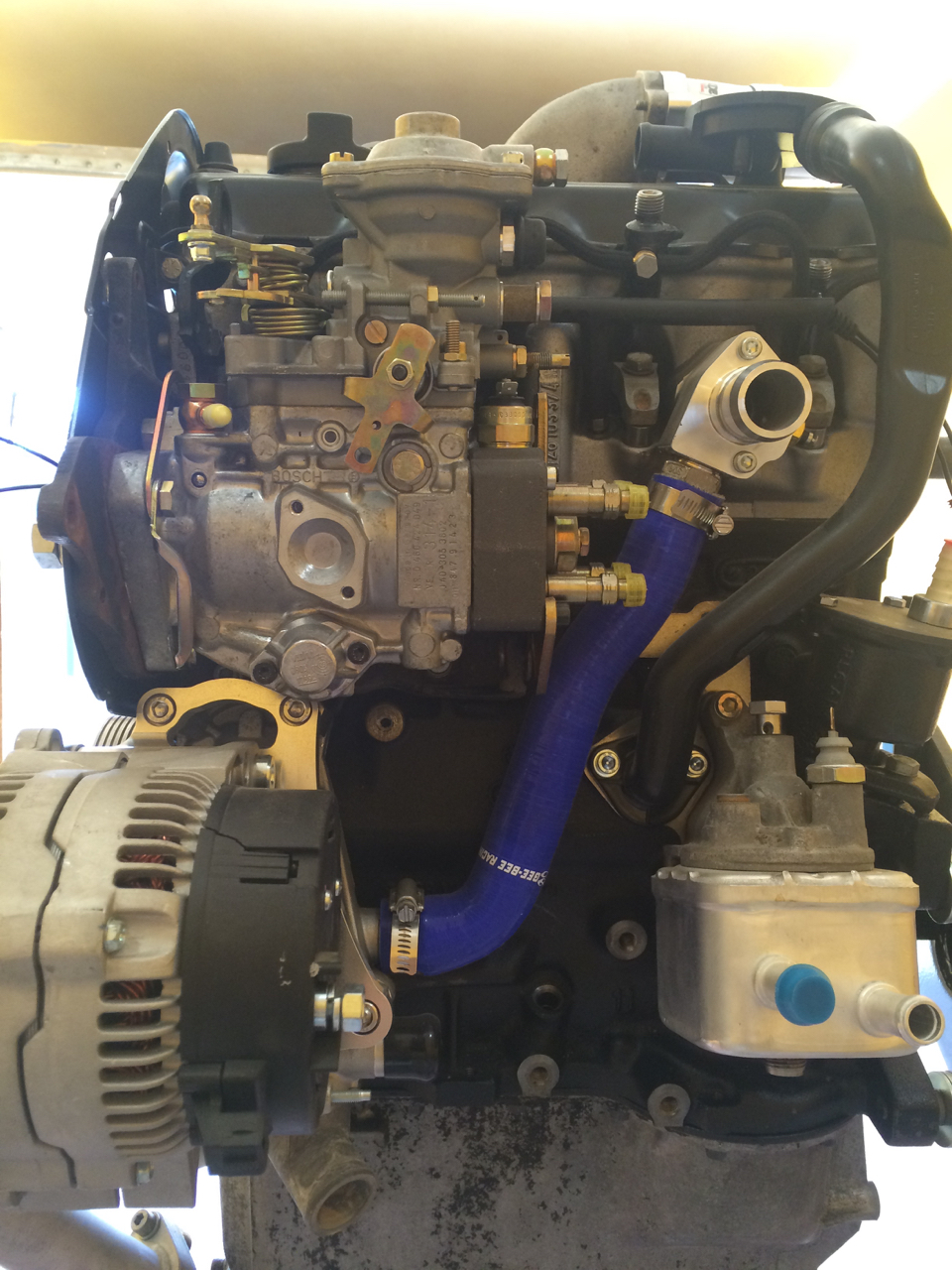

The Bosch VE / Cummings 4BT Injection Pump installed!

Videos

The mounting arms of on the IP #6 & #7 on the ETKA reference page can be confusing so here's a video on it:

Youtube Video of IP Arm installation to engine

Diesel Injection Lines Install

P/Ns

TDI AHU Steel Injector Fuel Lines - 028130301M/2M/3N/4N Injector Lines

Two sources I found new:

So, this is the one thing of my install, that wasn't as straight-forward. With the larger pump, I had to bend my lines a tad. This MAY not be required for another type of pump.

Photos

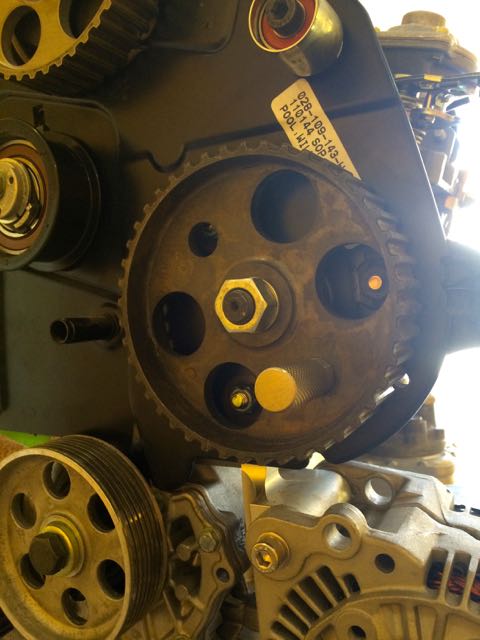

Diesel Injection Pump Sprocket Install

Reference

P/Ns

- 1x 028130111A - toothed belt pulley

- 1x N0127102 - woodruff key

- 1x N0122333 - washer

- 1x N0110212

Tools

- torque wrench

- 22mm socket

- Blue Thread Locker

- Universal Sprocket Buster Counterhold Tool

Photos

Install the toothed pulley where any VW markings face towards you. The orientation should be like this:

Installed:

Injection Pump Idler Pulley

Reference

P/Ns

- 1 x 028109244 - Idler Pulley

- 1 x N0147172 - bolt

Tools

- torque wrench

- Blue Thread Locker

- H6

Photos

Installed:

Camshaft Sprocket

Only real note for this is to grease the thick washer that comes with N90502103. It's been noted that some major corrosion can happen.

I lightly PTFE geased the center of the sprocket where the washer contacts it. I later do a light top coat once the bolt is torqued and installed.

Reference

P/Ns

1 x 069109111 - toothed belt pulley (camshaft sprocket)

1 x N90502103 @ 75Nm or 55ftlbs; VW states 45Nm / 33ftlbs ; further research appears this has been more problematic on ALH than 1z/AHU engines, but still good to do.

Tools

- Blue Thread Lock

- PTFE Grease

- Torque Wrench

- 18mm socket

Lightly grease of center of camshaft sprocket

TDC Process

So, now that you have everything on the engine sides, it's time to get serious about pulleys and belts.

This will walk through TDC of all but the flywheel. It's good practice for the n00b!

When you install the flywheel and TDC that, you'll want to make sure everything else is at TDC and then tighten the timing belt. It'll happen soon.

References

VW; W42-011-294-103B

Bentley; 23b-5 through 23b-9 p13-14 to 13-26

MyTurboDiesel AHU timing belt removal

MyTurboDiesel AHU timing belt installation

Tools

19mm socket

MetalNerd B4/mkIII timing beltnDeluxe kit

Ground Zero (TDC)

From a knowledgable person; Michael Courtenay on the Diesel Powered Vanagon FB group

"You can only verify TDC with the cam or injection pump after the engine is timed and the belt is on.

Obviously if you have no belt you cannot verify that #1 is at the top by anything other than the crank. Without a belt the cam and crank can move out of phase with one another, so you need a way to confirm each of them independent of one another, hence the plate, pin, and crank tool.

The Metalnerd crank pulley tool bolts to the face of the crank sprocket (with harmonic balancer removed, but with the crank bolt in place). The face of the sprocket has four M8 bolt holes. The holes are not in a perfect square, so the tool only bolts on one way, or 180 degrees out from that way. That would be with #1 at TDC or with #4 at TDC. Those two travel together on the crank though, and 2 & 3 travel together. In practice it doesn't matter which way it fits if the engine is not timed yet, because that then becomes #1 TDC.

Any marks on the dampener or flywheel are secondary and can be used to check crank position once the engine is in the vehicle. They are not necessary if you have the tool.

The tool does come with the Deluxe set. It is a round piece of metal with an ear bent perpendicular to it. If you hold it up to the crank sprocket it will be immediately obvious how it fits.

You can also check for TDC by dropping the oil pan and verifying that the piston is all the way up.

The notch on the rear of the camshaft is cut off-center so the locking plate will only fit into place when the #1 valves are in the correct position."

HOWEVER, you WILL want to recheck TDC after you mount the flywheel. This will though get you used to checking TDC on the Crank, IP, & CamShaft

Camshaft

You need to remove the valve cover

Photos

Valve Cover Removed

CamShaft set to TDC via turning on the sproket end

Injection Pump

Photo

This is what it'll look like when the pin is inserted

Videos

AHU Injection Pump Locking Pin You Tube Video

Crank

You need to set the crank to TDC. This is accomplished by turning it till you can set the crank lock tool

Photos

You'll want to turn the crank bolt shown below with a 19mm and turn it clock-wise to adjust fitment for the crank lock tool

Crank lock tool will fit on one way and look like the below

FlyWheel / Pressure Plate

To be able to get TDC set on this, the engine now needs to be removed off the stand and lowered.

This is a good time to mount the brackets & carrier bars and support the engine on that with some wood/blocks

See the page Carrier Bars & Brackets

Clutch

Get the following

LUK 17-050 DMF Clutch & Flywheel

Modified Bernd Jager TDI input shaft

Bernd Jager TDI flywheel cover plate

Transmission

I'm starting with an 82' diesel, so I *have* to upgrade my transmission or expect to blow shit up early on.

I'd love to go 5spd, but not knowing enough to go this route, I have decided on a rebuilt DK (80-82 air-cooled Vanagon transmission).

Most converting to a TDI should swap out their stock DV transmission for something else.

Tranny Upgrade Notes

The TDI will not have any difficulty cruising at 3500 or even a bit higher. The only downsides are noise and a bit of a drop in fuel economy. If your preference is to cruise at 65, then gear 3,000 @ 65MPH. With that gearing you will be able to cruise at 70-75MPH if need be and will still be high enough in the rpms @ 65 to develop enough HP for cruising with a 'cushion'.

Max torque on a stock TDI is around 2200 RPM. Max hp is around 3800 RPM. The TDI seems happiest in a Vanagon between 2600 and 2800 RPM. You are above the max torque, but well below the max hp. Your gearing and tires will dictate what speed that is. In this ratio, I would think a Westy would be more the range of 2700-2900rpm to account for the extra weight; ~700lbs last I heard!

Till a better place linkage differences here

Obtained a DK air-cooled transmission

Here are some good calculators:

Betsy's Decision

Since each setup is different for me I decided on the following:

It "is" possible to put a 5spd transmission in the 82' style setup, but you'll be having to play with linkage and the like. I've read of a few who have done it. It was a split down the middle if it was worth the trouble than just going the 4spd.

For this reason, MOST people who do an 82' diesel conversion just roll with a DK (80-82 air-cooled Vanagon) transmision with a taller 3rd & 4th gear. As it will fit with the diesel vanagon bell-housing attached to it.

AA Transaxle - Rebuilder

My rebuild included:

- 3rd 1.12

- 4th 0.70

- LSD

For my tires my RPM ratios look like:

4.571 FD @ 0.70 - 2672 @ 65mph

4.571 FD @ 0.70 - 2878 @ 70mph

Transaxle to Engine Mounting

IN PROGRESS

Reference

Terms

So, there's a ton of slang in this portion of the engine. Why? I don't know, people must be fucking bored.

- Service Manual | Slang | Abbv.

- Clutch Release Bearing | Throw Out Bearing | TOB

- Needle Bearing | Pilot Bearing | NB / PB

P/Ns

These should ideally be replaced if going through the trouble of redoing a transmission:

- 056105313C = needle bearing

- 091141165D = clutch release bearing or a more modern p/n 113141165B

- 016141181 = clutch release bearing guide tube, if needed

Mounting Bits

If you're transfering your DV components for the conversion, KEEP your diesel bell housing bolts that go into the engine.

If you're in Europe you can get the bolts from BrickWerks

If you're like myself in the USA, and starting with no previous DV parts to work with finding those bolts can be a real PITA. Fortunately, I got an awesome reply from syncroserge with the following information:

All bolts, no studs. ETKA is both inaccurate and incomplete on this. The starter bolts are in: Electrical Systems, Starter and Single Parts, diesel eng.

- 2x M12 x 1,75 x 122mm, N 040 350 1

The one on the clutch slave has no washer.

On the other side of starter washer is:

- A13 x 24 x2,5 , N 011 531 7

For the rest of the block. in Engine, Clutch, look under cylinder block with pistons, oil sump

Then next 2 are:

- M12 x 1,75 x 80mm, N 010 464 4, both with same washer as above.

At bottom of block,

- M12 x 1,75 x 100mm, N 010 458 2, washer same as above, nut:

- M12 x 1,75, N 011 030 4

Two bolts from bellhousing to oil pan (never found those in ETKA):

- M10 x 1,5 x 65mm, N 010 465 9, both with washers:

- A10,5 x 21 x 2, N 011 527 11

Marking new TDC on TDI Flywheel & Pressure Plate

There are a few methods of obtaining a TDC mark on the Diesel Vanagon TDI Conversion setup. Ideally, if you have the OE DV pressure-plat and fly-wheel, you can bolt that up to the new TDI Flywheel/pressure plate and make your mark.

However, if you don't you can mark the TDI pressure plate with a hack.

References:

1z/AHU FlyWheel marking for T25

TheSamba - Great method via going through the 1st cylinder GP or Injector hole

Justin Sores had a good mention;

"The notch is to be made on the tranny side of the flywheel, not the engine side. In anycase, carefully marking the flywheel allows you to later mark the PP with confidence and also ensures that if you ever have to change out the PP at a later date, you already have a solid reference point on your flywheel."

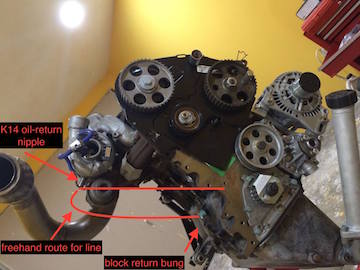

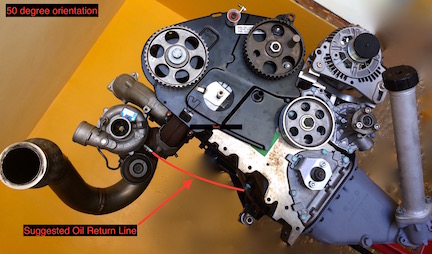

Turbo Oil Return Line to Block

When you don't use the AAZ exhaust manifold, you generally tap to the oil pan for the oil-return instead of going into the AHU block.

Since, we have an AAZ exhaust manifold, we're going to do it right!

Reference

K14 oil drain to block port size/thread M16x1.5, but I have heard also M18x1.5. The block end is M18x1.5

Photos

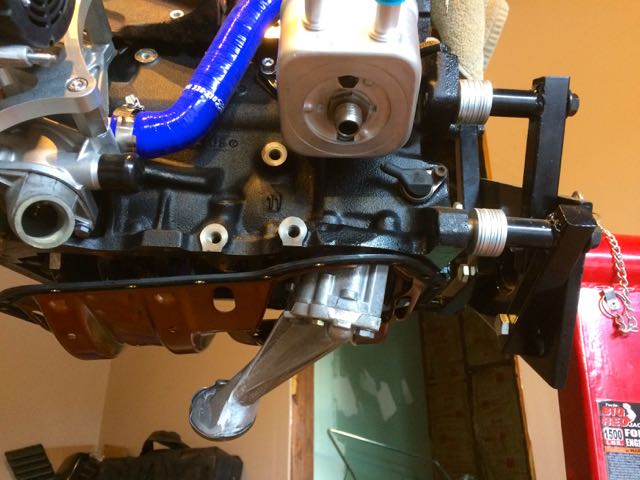

This was my first photo of the attempt. It appears I need to clock my drain / turbo

Phase two with reclock

Engine Carrier Bars & Brackets

IN PROGRESS

Ah carrier bars. So, there's the 82' style which was an one-off in the USA and then 83+ which was when the engine got pushed back roughly 2" towards the rear to accomodate for a longer WBX transmission.

When you have an 82' diesel, it make sense to keep that arrangement. It's also been argued by some the 82' style allows easier access for working on the engine, as it's not 2" closer to the rear.

Upgraded 82' Bars

It's known that the 82' bars provide more vibration which some will argue. Myself when I researched the interwebz the general consensus was that they are not as good with vibrations compared to the newer 83' style carriers. Most people don't even notice a real difference. However, with my physical health, I will do whatever I can to make it more comfy.

Also, the cross-member that connects the two carriers that goes over the oil-pan is a very weak link. I have read where others have used a stonger tube bar to help it from twisting over. Because the 83' carriers don't have the rubber bushings on the ends there's no requirement for the cross member bar.

That said, I went with 83' style bars, but just not ANY 83' bars though, Tony @ TSI-Engeering found on TheSamba makes.

I got a set of his 83' 2WD Carrier bars and then moved the motor brackets (had him lightly mark them where he installs) and then moved it towards the front of the van 2".

I then installed his Isolator Mountes which use VW P/N 357199402BMY (Meyle has a better fitment with the isolator bracket I've read).

This allows for a more modern and easily found engine mount.

Reference

ETKA - 82' engine brackets bonded rubber bush F >> 24-C-175 000 1.6ltr. DIESEL:CS

TheSamba - '82 vs. '83 diesel engine carrier bar differences

P/Ns

- 3 x N0102584 - bolt

- 3 x N0122422 - washer

- 3 x N01152711 - spring washer

- 1 x N01101011 - nut

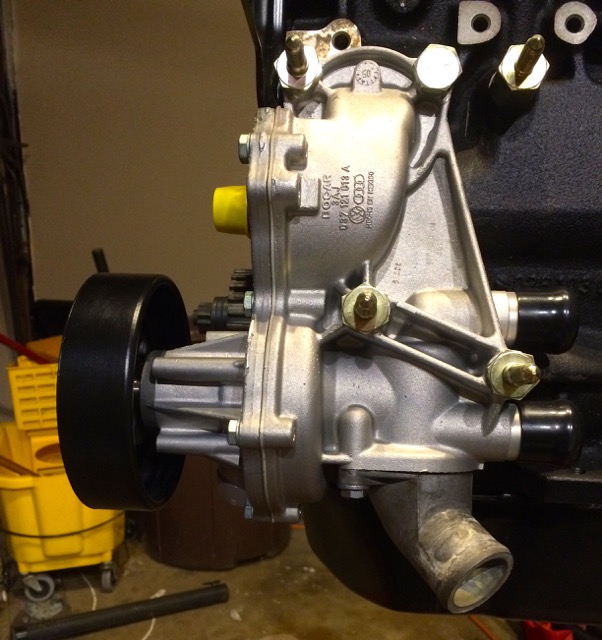

Driver Side Bracket

If you use a larger turbo you'll need to fabricate a bracket that'll fit it.

Photos

Driver Side

Driver Side Stock 82' Diesel Vanagon engine bracket

Passenger Side

Passenger Side Stock 82' Diesel Vanagon engine bracket

The Details (my collected research before above work)

There's a decent article on TheSamba about what parts you'll need

http://www.thesamba.com/vw/forum/viewtopic.php?t=410813&highlight=ahu+intake

What isn't needed from stock AHU Engine

If going mTDI the following are not required:

- electrical harness

- MAF sensor

- MAP sensor

- IAT sensor

- Injector #3 needle lift sensor

- Fuel temp sensor (inside IP)

- N75 & N18 valve

- Crank Speed Sensor; you just need to plug the hole up which the sensor without the wire does well at. However, that looks tacky and leaves a busted sensor. The other option is to buy a plug:

Turbo

This is one of the "variables" that varies for what you want. The most common turbos tend to be:

- K03

- GT1548

- Holset HE 200

- K14

Injector nozzles

This is one of the "variables" that varies for what you want. The most common setups tend to be:

- Bosio Power Plus 520 (PP520)

- DLC764

Air Filter

Good writeup on using the Donaldson

Donaldson filter G065433 install

Engine Mounts

Research

One method I was looking at was using SAAB Hydraulic mounts as seen here

Frank Grunthaner SAAB Hydraulic mount setup

http://www.thesamba.com/vw/forum/viewtopic.php?t=403215&highlight=ahu - rsxr - Saab engine mounts

I then discovered Tony Sanchez (TSI Engineering) who makes Syncro and 2wd 83+ carrier bars.

Now, this got me thinking about what the differences between 82' and 83' style carrier bars.

The newer 83+ bars move the motor brackets that are welded on the carrier bars back towards the rear of the van. This was done to allow for longer transmissions in the later years.

However, no one makes 82' style new carrier bars. To me the newer style is ideal for the following reasons:

- They are solid mounted at the end of the carriers and not rubber NLA (yet supposedly accesible) bushings

- There is no need for a cross member across the oil-pan to help 'stablize' it.

- Supposedly the newer bars help reduce vibration which for a diesel is high on my list.

I have a set of TSI Engineering bars, which I plan to remove the motor bracket mounts and move them in position as where they would be on the 82'

Clutch

These two are highly recommended:

LUK 17-050 - less vibration

Sachs VR6 Clutch Kit - slightly more torque

I am planning to go with the LUK 17-050

http://www.vw-t3-bus-shop.de/en/19-tdi-modification-parts-for-vw-t3-bus

http://www.vw-t3-bus-shop.de/en/adapter-plate-for-turbo-diesel-gearbox-on-golf-starter -this adapter nicer than the switch a motor since its recessed for the starter alignment

http://www.vw-t3-bus-shop.de/en/clutch-dorn/gearbo...ion-to-org

http://www.vw-t3-bus-shop.de/en/abdeckblech-zum-schwungrad-aus-edelstahl

Intercooler

Oil Pump

P/N:

- 068-115-105-BP

This is the DV oil-pump which is required if using the DV oil-pan

Oil Cooler

http://www.thesamba.com/vw/forum/viewtopic.php?t=603839&highlight=ahu+water+pump

P/Ns

- 027117021E cooler

- 028115721B tube

Exhaust

4 bolt trapezoid MK2 AAZ exhaust manifold P/N 068-129-591G

Part Purchase Notes

NOTE: some of these parts you can obtain from the used engine. However, as I want to use the used engine for another project someday, I rather replace what I need for it on the new long-block. Everything below takes a Long-block 1Z/AHU as the base up to an installable engine.

I don't include pricing since that's a fluxing item whereas a part description / number won't.

Engine

Alternator

P/Ns

- 028903119AA - Clutched Alternator Pulley (you'll need a tool/socket for this ebay search PULLEY CENTER BOLT REMOVAL ALTERNATOR BOSCH SOCKET TOOL FOR PEUGEOT VW AUDI FORD)

TDI Alternator

VWDiesel.net Thread: W Terminal on TDI Alt

A AL0184X 120a alternator will work and includes a W spade

1997 Jetta 1.9 TDI alternator 90a

You'll want to find alternator bracket 028903143AB

ABF Alternator

I went with an ABF Serpentine setup which uses 028 903 029 M/Bosch AL0185X as the alternator

Turbo

4 bolt trapezoid MK2 AAZ exhaust manifold P/N 068-129-591G & flex down-pipe 3" & K14 Turbo

Turbo was purchased from Tony Sanchez from a 50 degree setup of his.

Installation

The four bolts that are used to mount the turbo to the flange are done @ 35Nm or 26ft lb

IC - A2A

SAAB Classic 900

Silicon Coolant Hose Kit

From GeeBee from TheSamba